Logotub can create standard pipes starting from the most common macros: round, rectangular, and rectangular with round corners.

It is possible to draw the pipes starting from a 2D closed profile as well.

The 2D geometry can easily be projected on the tube surface while with the 3D module it is possible to read IGS files coming from external 3D CAD systems.

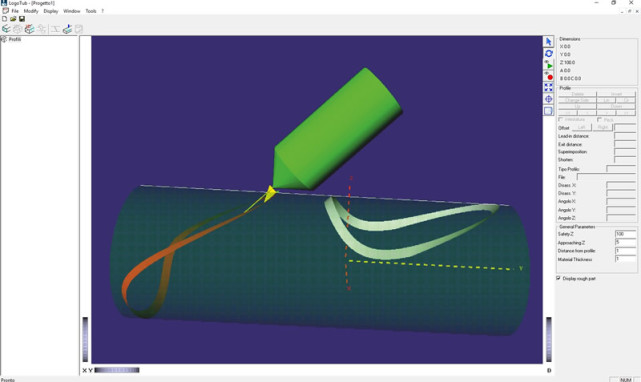

The 3D engine included in Logotub offers the user a real view of the tubes before starting the cutting operations on the machine.

Intersections between pipes are automatically computed:

- starting from a standard tube it is possible to choose the profile of the tube to couple and its position; it is so possible to compute intersections between pipes decentred according to the rotary axes;

- the inclination is free (consistently with the degrees of freedom of the machine);

- the intersections can be through and non-through

- 2D geometry projected or surface mapped on the tube surface

- complete or partial chamfers are available and can improve the welding operations on significant pipe thickness