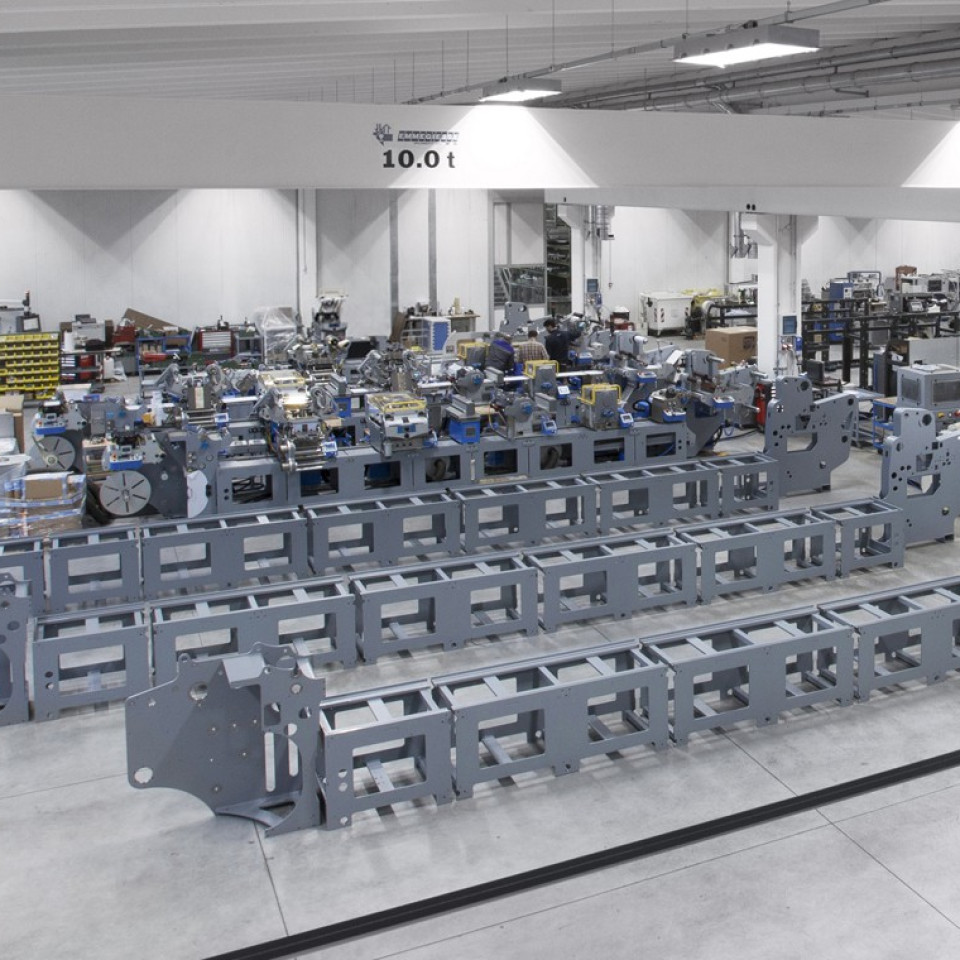

CARTES, since 1970, has been producing machines for labels. The headquarters of the company, in which it operates highly qualified and experienced personnel, covers an area of 10,000 m2 in Moglia, in province of MANTOVA.

We met Enrica Lodi and asked her about her experience with Taglio software.

What is your company business?

CARTES offers the widest range of label machines with hot stamping, screen printing, printing/painting flexographic, flat die-cutting, semi-rotary die-cutting, relief and LASER technology for die-cutting and converting.

CARTES was the first in the world to believe, develop and industrialize the LASER technology applied to the die-cutting of self-adhesive labels.

Today, after 19 years and more than 300 LASER machines installed in 45 countries, the LASER CARTES technology is a success confirmed and recognized in the world, not only for the level of achieved, but also because of the possibility of being integrated with hot foil stamping units, screen printing, flexographic, flat cutting, semi-rotary and relief cutting.

Combined machines are highly appreciated by manufacturers of labels because they make it possible to process several items in a single cycle and obtain labels of the highest value.

What are the reasons for which your company has chosen TAGLIO software?

CARTES was looking for a reliable technology partner having an adequate knowledge of specific issues of the Galvanometric Laser Systems sector and of the management of the machines controlled by Automatic Numerical Controls.

The objective was, and is, to be able to provide an interface totally in "Touch" style (Tablet type) to be used by operators on board of the machine in a simple way and as automatic as possible in order to reduce to zero the setup time of the cutting layouts.

TAGLIO showed us a CAM environment, already specifically developed for a "TOUCH" approach, One Finger, which was used for the customization for our machines.

What CAD/CAM solutions were used previously?

The solution previously adopted was based on a CAM product specifically developed in-house.

This product has followed the technological evolution of the different versions of the machines produced.

Although it is functional, over time it has begun to show the operating limits and differences that can no longer be tolerated in a market in continuous evolution.

What are the assets of Taglio software?

Often requests for solutions of specific needs have been satisfied in a very short time thanks to the availability of algorithms or functionalities already developed and tested.

In particular, it is very appreciated the modern approach of the working environment on board machine and the ease switch from drawing to cutting also in case of problematic drawings.

You can't forget the quality and timeliness of SERVICE. Always available in all cases where there is a need of immediate support for the solution of special or complicated situations.

What are the results achieved with TAGLIO software?

Thanks to the partnership with TAGLIO, we have been able to confirm our position of World Leader in the market of CONVERTING and LASER die-cutting.

Our new high-productivity and high-versatility machines are fully managed by the software supplied by TAGLIO.

Features such as JOB mode,cut layout change in continuous , completely free numbering (both in the use of TTF fonts and incrementing modes), multi LASER and many others, have been realized, optimized and are currently in use by dozens of end users with full satisfaction.