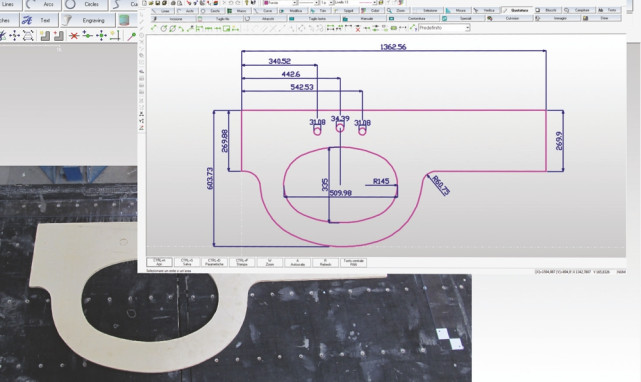

One of the most frequent problems of the users who cut stone materials and glass with CNC machines is the large amount of parts left over from existing templates or duplicated on construction sites.

Dime is the option of the CAD software Logotag to digitize wood and plastic templates or paper drawings. Dime is oriented to the digitization of two-dimensional planar shapes, such as kitchen tops and bathroom tops, tables and windowsills. It is designed to process digital images, representing any shape.

With a digital or an industrial camera, the system is able to capture the image of the template to duplicate and create the drawing in a digital format (TAG, DXF or DWG) with minimal user control.